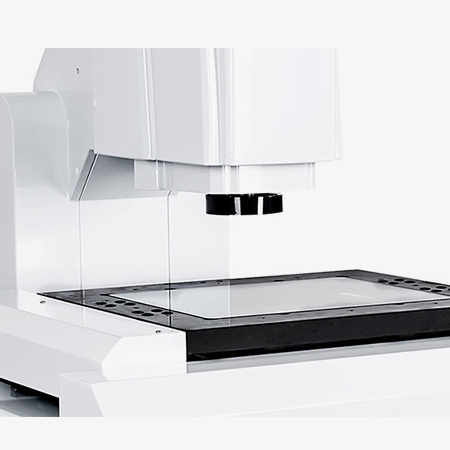

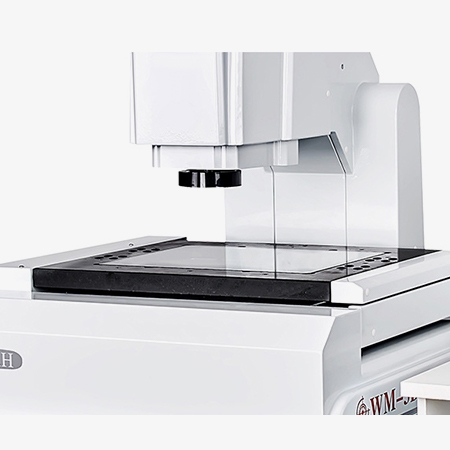

The SISCO automatic vision measuring machine uses high-precision XYZ linear guides and grinding-grade ball screws for smooth, long-lasting motion. A 1/2" HD digital camera (28–165x zoom) enables micron-level detail detection. The VMM measuring machine's dual-mode cold light source offers stepless brightness control, adapting to various surface types and ensuring stable illumination for precision optical measurements.

Intelligent Edge Detection & Ultra-Fast Positioning

- Dual-CCD cooperative edge detection: Independent operation of main and auxiliary cameras—main camera for large field positioning, auxiliary camera for fine-detail edge detection—boosts edge-finding efficiency by over 30%.

- Multi-mode edge detection algorithms: Our image measuring instrument supports over 10 strategies including edge matrix capture, arc fitting, and intersection recognition, perfect for measuring irregular metal parts and curved electronic components.

- Dynamic learning optimization: The video measuring system remembers frequently used edge parameters and allows one-click setup, reducing repetitive configuration time.

High-Precision Plane Measurement with Universal Adaptability

- Optical image-based height measurement: This visual measuring machine combines laser triangulation with image autofocus algorithms for ultra-precise 0.1μm measurements of flatness, step heights, and hole depths.

- Mesh & stencil inspection: Automatically recognizes mesh nodes and calculates aperture uniformity and deformation.

- Textile hole measurement: Suited for micron-level yarn hole inspection, supporting analysis of hole density and diameter distribution.

Multi-Virtual Measurement & 3D Smart Analysis

- 3D surface reconstruction: The CNC vision system generates 3D morphology maps through multi-angle image stitching, providing detailed surface visualization.

- Flatness 3D reporting: Displays flatness deviation in intuitive colored cloud maps (±50μm range), with support for 2D/3D views for quick defect localization.

- CAD import and comparison: Supports DXF/IGES format drawing import and automatically calculates deviation between actual and design dimensions, outputting an error heat map to guide process improvement.

Applications

Video measuring machines are widely applied in precision industries like PCB manufacturing, new energy, semiconductors, and 3C electronics. They ensure accurate inspection of circuit layouts, battery components, solar cells, wafers, and phone housings. With micron-level, non-contact measurement, these systems help improve product consistency, assembly quality, and dimensional accuracy across various high-performance applications.

New Energy

Semiconductors

3C Electronics

PCB Manufacturing

| Model | SISCO-VMM-CNC-4030AH | |

| Worktable | ||

| X/Y Axis Travel | 400 × 300 (mm) | |

| Z Axis Travel | Effective space: 245mm; Focusing travel: 200mm; Working distance: 90mm | |

| Metal Stage Size | 550 × 450 (mm) | |

| Glass Stage Size | 430 × 330 (mm) | |

| Transmission System | Precision linear guide rails and ground ball screw for X/Y/Z axes | |

| Measuring Servo Drive System | ||

| Scale Resolution | 0.0002 mm (0.2 μm) for X/Y/Z axes | |

| Measurement Accuracy | ≤ 3 μm + L/200 | |

| Repeatability | ≤ 3 μm | |

| Motor System | High-performance servo motors on all three axes with dual closed-loop control | |

| Imaging System | ||

| Camera | 1/2" high-definition digital camera, video magnification: 28–165x | |

| Lens | High-definition zoom lens, continuous magnification: 0.7–5.0x | |

| Optional 0.5x Objective Lens | Total magnification: 14–83x | |

| Optional 2x Objective Lens | Total magnification: 56–330x | |

| Illumination System | ||

| Light Source | Surface and contour cold light sources, long lifespan, brightness adjustable | |

| Dimensions & Weight | ||

| Machine Dimensions | 800 × 900 × 1650 (mm) | |

| Machine Weight | 380 kg | |

Q1: What is a video measuring machine?

A1: A video measuring machine (VMM), also known as a vision measurement system, is a non-contact inspection device that uses optical imaging and software algorithms to measure the dimensions of parts with high precision. It typically includes a camera, zoom lens, light source, and motorized stage, making it ideal for measuring micro-scale or delicate components in electronics, semiconductors, and precision machining.

Q2: What is the use of the VMM machine?

A2: VMM machines are used for accurate dimensional inspection and quality control in applications where high-resolution, non-contact measurement is required. They are widely used in PCB inspection, semiconductor packaging, medical devices, 3C electronics, and automotive parts to check features like length, diameter, flatness, and alignment.

Q3: How accurate is machine vision?

A3: Modern video measuring machines offer micron or sub-micron range accuracy, depending on the system configuration and measurement conditions. Advanced models ( such as SISCO's automatic video measuring machine) can achieve measurement accuracy as high as ≤3μm + L/200 and repeatability of ≤3μm, making them highly reliable for inspecting critical components.

Tips: What is the difference between VMM and CMM?

While both Video Measuring Machines (VMMs) and Coordinate Measuring Machines (CMMs) are used for dimensional inspection, their working principles and applications differ:

- VMM uses a camera and optics for non-contact 2D or 2.5D measurements, ideal for small, delicate, or soft components such as PCBs, wafers, or smartphone parts.

- CMM typically uses a tactile probe for 3D contact measurement, suitable for metal parts, castings, and mechanical components with deeper geometries.

VMMs excel in speed and resolution, especially for intricate features, while CMMs offer robust 3D volumetric measurement for heavier parts. Choosing the right system depends on your part type, required precision, and production needs.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.