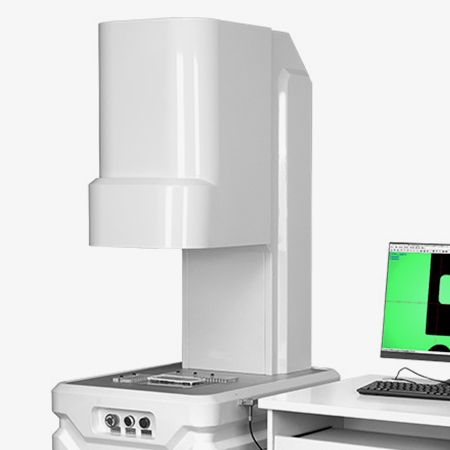

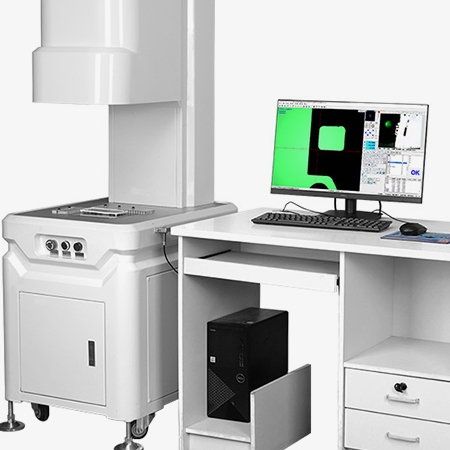

Our fully automatic one-click vision measuring machine features a dual-sensor imaging system, combining a 10MP 2/3" CCD and a 20MP 1" CCD for superior image clarity. The VMM measuring machine is exceptionally easy to use and has an integrated compact design. Supporting full-field imaging and single-click operation, this vision measuring system significantly improves measurement efficiency without requiring manual focusing or alignment. It's the ideal choice for high-speed, high-accuracy quality inspection in modern production lines.

Intelligent Auto Recognition & Simultaneous Multi-Point Measurement

- Place components at any angle within the field of view; the video measuring system will automatically recognize the part, match the template, and begin measurement.

- This optical measurement equipment is capable of measuring up to 500 points simultaneously, even across multiple components, with fast and precise results.

- High-resolution telecentric lens combined with sub-pixel imaging technology (1% accuracy) ensures reliable dimensional analysis.

- Automatic feature recognition delivers consistent and stable measurement output every time, supporting high-efficiency batch inspection.

Easy Operation with Real-Time Reporting

- Simple, intuitive operation of the VMM measuring machine requires only minimal training, which is ideal for production line personnel.

- The user-friendly interface with clear icon-based controls makes every measurement function easy to locate and execute.

- Instantly evaluate measurement deviations and generate statistical analysis and inspection reports with a single click.

- All data can be automatically compiled into Excel reports, making the vision measuring system easy to track inspection history and export results for further analysis.

Applications

Video measuring machines are widely applied in precision industries like PCB manufacturing, new energy, semiconductors, and 3C electronics. They ensure accurate inspection of circuit layouts, battery components, solar cells, wafers, and phone housings. With micron-level, non-contact measurement, these systems help improve product consistency, assembly quality, and dimensional accuracy across various high-performance applications.

New Energy

Semiconductors

3C Electronics

PCB Manufacturing

| Model | SISCO-VMM-WM-200 | |

| Measuring Range | Φ200 mm | |

| Field of View | 190mm*127mm | |

| Measurement Accuracy | ±8 μm | |

| Display Resolution | 0.1 μm | |

| Depth of Field | 60 mm | |

| Image Sensor | 20MP CMOS, 10MP 2/3'' CCD, and 20MP 1'' CCD | |

| Monitor | 24-inch LED display, resolution 1920*1080 | |

| Receiving Lens | Dual telecentric lenses | |

| Illumination System | Ring-shaped telecentric parallel light source | |

| Telecentric Lens | Dual-sided telecentric parallel optical path lenses | |

| Backlight Transmission | Telecentric transmitted green illumination | |

| Software | Dedicated one-click measurement software | |

| Z-axis Motorized Stage | Travel Range: 100 mm (optional) | |

| Z-axis Scale Accuracy | / | |

| Subpixel Processing | 30:01:00 | |

| Measurement Speed | ≤2 seconds | |

| Power Supply | 100~240V AC; 50~60Hz; 2A 300W | |

| Operating Environment | Temperature: 5°C~35°C; Humidity: 20%~80%; Vibration: <0.002g at <15Hz | |

| Dimensions (L×W×H) | 600*650*1650(mm) | |

| Weight | 80 kg | |

| Function | Description | |

| Measurement | Supports precise geometric measurement of distances, lengths, circle diameter/radius, circumference, area, angles, arcs, rectangles, ellipses, points, and lines directly on the captured image. | |

| Report Export | One-click export of measurement reports in JPG, BMP, Word, Excel, or PDF formats. | |

| SPC Analysis | Generates X-R and Xm-R control charts, automatically calculates Max, Min, Mean, Standard Deviation, Offset, Ca, Cp, and Cpk. | |

| CAD Comparison | Imports DXF format image data for real-time overlay comparison with actual measurements or AutoCAD drawings. | |

| Tolerance Calculation | Automatically calculates deviation between measured values and nominal values based on user-input tolerance range. | |

| Inline Inspection (Optional) | Supports automatic inspection of product dimensions, defects, and color to determine pass/fail status. | |

Q1: What is VMM in measurement?

A1: A VMM (Video Measuring Machine) is a non-contact optical inspection system that uses high-resolution cameras, precision lenses, and image processing algorithms to measure the dimensions and geometry of objects. VMMs are ideal for inspecting complex parts in electronics, precision engineering, and medical device manufacturing, offering high accuracy, repeatability, and efficiency.

Q2: What is an optical measuring machine?

A2: An optical measuring machine is a type of non-contact inspection system that uses optical technologies, such as telecentric lenses, lighting systems, and cameras, to capture and analyze the shape, size, and position of components. These machines are widely used in quality control for industries like PCB manufacturing, semiconductors, and 3C electronics. They are also referred to as video measuring machines or vision measuring systems.

Q3: What is the optical measuring method?

A3: The optical measuring method relies on capturing the 2D or 3D image of a part and analyzing its geometric features using digital image processing. This method enables fast, accurate measurements without physically touching the part, making it suitable for delicate or micro-scale components. It’s commonly used in video measuring machines for measuring lengths, angles, radii, and contours with sub-micron resolution.

Tips: What are the four basic types of machine vision systems?

There are four basic types of machine vision systems commonly used in industrial automation and precision measurement:

- 1D Vision Systems: Analyze data along a single line, often used for scanning barcodes or edge detection.

- 2D Vision Systems: The most common type, used in video measuring machines to capture flat images and analyze surface geometry.

- 3D Vision Systems: Capture depth and volume information, suitable for inspecting height, flatness, or complex 3D profiles.

- Smart Vision Sensors: Compact, integrated systems that combine image acquisition and processing in one unit for fast decision-making on production lines.

These machine vision technologies are foundational for modern optical measuring systems, enabling automated, accurate, and high-speed inspections across various industries.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.