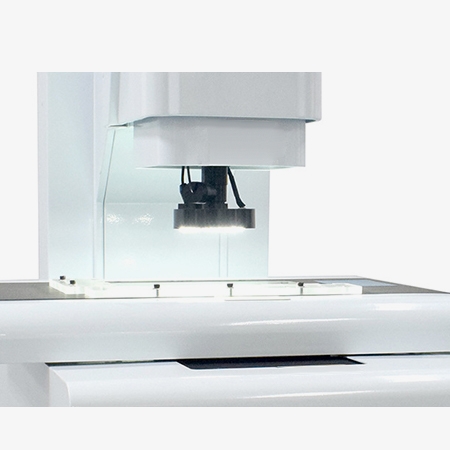

Built on advanced CCD digital imaging technology, this optical video measuring machine quickly and accurately reads displacement data from the linear scale. The VMM measuring machine utilizes a powerful software module based on spatial geometry algorithms to instantly generate measurement results displayed as graphics on the screen. By comparing real-time images with reference diagrams, operators can easily identify measurement deviations, significantly improving both measurement accuracy and reliability.

Intelligent Imaging & Contour Detection

- Equipped with high-performance contour scanning capabilities, this vision measuring system can precisely capture the edge details of the workpiece and automatically generate 2D CAD drawings.

- Advanced image stitching and high-resolution capture features allow the CNC vision system to create ultra-clear images of up to 20 megapixels.

- The surface edge detection function supports multiple edge-finding modes, adapting to different shapes and measuring scenarios.

Precision Measurement & Industry-Specific Capabilities

- Leveraging optical imaging technology, the vision measuring system enables accurate focus and measurement of both height and surface plane.

- Integrated with industry-specific functions such as mesh board measurement, textile hole inspection, screen printing pattern alignment, and PCB target pattern detection.

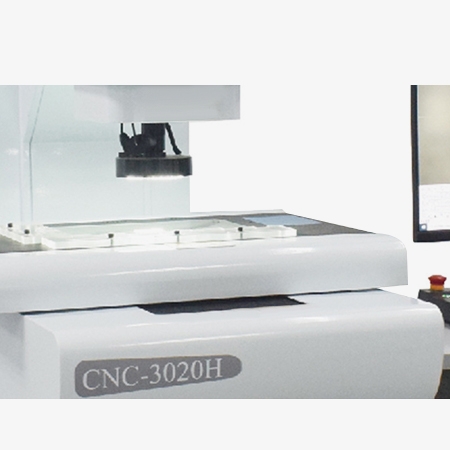

- The X, Y, and Z axes are fitted with THK precision linear guides and THK ground ball screw drives, ensuring high transmission accuracy, long service life, and exceptional stability.

Advanced Lighting & Report Output Options

- Capable of generating 3D flatness reports in both 2D and 3D formats, the optical measurement system provides a visual representation of flatness for quality analysis.

- Supports CAD import and virtual measurement comparison, enabling users to overlay actual measurement data with design files for deviation analysis.

- Comes standard with a programmable five-ring eight-zone surface light, LED contour lighting, and coaxial illumination. Optional colored light sources are available to match different product materials and inspection requirements.

Applications

Video measuring machines are widely applied in precision industries like PCB manufacturing, new energy, semiconductors, and 3C electronics. They ensure accurate inspection of circuit layouts, battery components, solar cells, wafers, and phone housings. With micron-level, non-contact measurement, these systems help improve product consistency, assembly quality, and dimensional accuracy across various high-performance applications.

New Energy

Semiconductors

3C Electronics

PCB Manufacturing

| Model | SISCO-VMM-CNC-3020H | |

| Worktable | ||

| X/Y Axis Travel | 300 × 200 (mm) | |

| Z Axis Travel | Effective space: 245mm; Focusing travel: 200mm; Working distance: 90mm | |

| Metal Stage Size | 450 × 350 (mm) | |

| Glass Stage Size | 330 × 230 (mm) | |

| Transmission System | X/Y/Z Axis: THK precision linear guides + THK ground ball screws | |

| Measuring Servo Drive System | ||

| Linear Scale Resolution | 0.0001 mm (0.1 μm) for X/Y/Z axes | |

| Measurement Accuracy | ≤ 2.5 μm + L/200 | |

| Repeatability | ≤ 2.5 μm | |

| Servo Motors | Closed-loop high-performance servo motors on X/Y/Z axes with dual closed-loop control | |

| Imaging System | ||

| Camera | 2/3" 3.2MP HD digital camera; Video Magnification: 30–190× | |

| Lens | High-definition zoom lens, Continuous zoom range: 0.7–5.0× | |

| Optional 0.5x Objective Lens | Total magnification: 15–95x | |

| Optional 2x Objective Lens | Total magnification: 60–380x | |

| Illumination System | ||

| Light Source | Surface Light + Telecentric Profile Light + Coaxial Light (long-life, dimmable LED cold light) | |

| Dimensions & Weight | ||

| Machine Dimensions | 750 × 850 × 1650 (mm) | |

| Power Supply & Power Consumption | 220V / 50Hz, 800W | |

| Glass Load Capacity | 30 kg | |

| Machine Weight | 300 kg | |

Q1: What industries commonly use a high-precision vision measuring machine?

A1: High-end fully automatic vision measuring machines are widely used in industries that demand ultra-precise dimensional inspection, such as precision machining, electronics, hardware manufacturing, plastic injection molding, and medical device production. Their high resolution and automatic operation make them ideal for batch inspection of complex components.

Q2: How accurate is a fully automatic video measuring machine?

A2: The measurement accuracy of a high-precision CNC video measuring machine can reach ≤2.5μm + L/200. Equipped with high-resolution linear scales (0.1μm), closed-loop servo motors, and advanced image processing software, these machines ensure stable and repeatable results even for intricate geometries and micro-scale parts.

Q3: What are the advantages of using an automatic vision measuring system over manual inspection tools?

A3: Compared to manual tools, a fully automatic vision measuring system offers significantly higher accuracy, faster throughput, and minimal human error. Features like automatic edge detection, programmable measurement routines, 2D/3D CAD comparison, and smart image stitching make it a powerful solution for high-efficiency quality control.

Tips: How to maximize efficiency in vision measurement?

To get the best performance from a high-end vision measuring system, ensure optimal lighting setup (e.g., using programmable ring lights or coaxial illumination for different surfaces), regularly calibrate the machine, and use CAD import functions for fast tolerance analysis. Proper training of operators also plays a key role in maximizing throughput and repeatability.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.