Electrostatic detector is a non-contact tester, which can quickly detect the static electricity on the surface of the object. When the positive charge indicator light is on, the positive charge electrostatic is detected; when the negative charge indicator light is on, the negative charge electrostatic is detected; if neither light is on, the surface of the measured object is not detected.

Equipped Indicator Lights

- Instant Visual Feedback. The primary advantage of an indicator light is the immediate visual confirmation of electrostatic charge presence. When the positive charge indicator light (red) is on, the positive charge electrostatic is detected; when the negative charge indicator light (blue) is on, the negative charge electrostatic is detected.

- User-Friendly Operation. The visual simplicity of indicator lights makes the electrostatic field detector more user-friendly. Users can simply look at the lights to understand.

Non-contact Measurement, Convenient to Use

- Safer for Sensitive Materials. Non-contact electrostatic detector is ideal for measuring electrostatic charges on delicate or hazardous materials. For instance, semiconductor wafers, and thin films can be easily damaged by physical contact. The non-invasive approach avoids mechanical stress or contamination, reducing the risk of defects and maintaining product quality.

- Versatile and Convenient Applications. This kind of ESD testers are highly versatile and can be applied in industrial, laboratory, and cleanroom environments. Their portability and ease of use make them suitable for monitoring electrostatic hazards on product.

- Long-Term Durability of the Device. Because the device does not require repeated contact with surfaces, it experiences less wear and tear, extending its service life.

Applications

SISCO's static field meter plays a vital role in environments where static electricity can affect processes, product quality, or safety. Such as is cleanrooms and laboratories, where static can attract dust and contaminants, potentially affecting precision experiments. Electrostatic field meters are also used in plastics, textiles, and film production.

Cleanroom

Textile Production

Plastic Production

Laboratory

| Model | SISCO-EFT-JED100 |

| Sensing Range | 100V~200KV |

| Power Supply | Double 3V CR2030 batteries |

| Operating Temperature | 0~50 ℃ |

| Measuring Distance | 10mm (best) |

| Response Time | 1s~3s |

| Measurement Mode | Handheld non-contact measurement |

| Material | ABS |

| Dimension | 80mm*60mm*25mm |

| Net Weight | 76g |

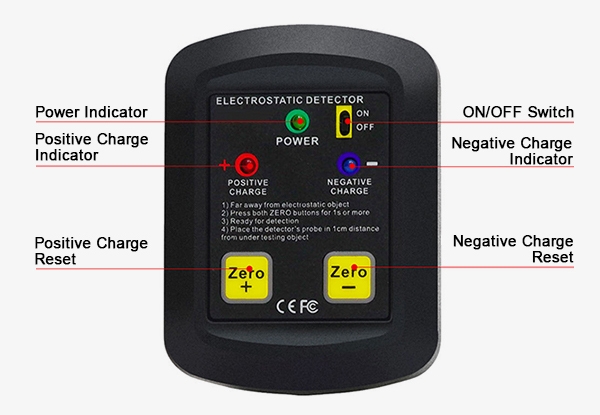

Structure:

Q1: What is electrostatic detector?

A1: This electrostatic field detector is a device used to measure the static on a surface without making physical contact (10mm is the optimal distance).

Q2: How does an electrostatic detector work?

A2: It detects electrostatic charges by sensing the electric field generated by charged objects. When the positive charge indicator light (red) is on, the positive charge electrostatic is detected; when the negative charge indicator light (blue) is on, the negative charge electrostatic is detected; if neither light is on, the surface of the measured object is not detected.

Q3: Can an electrostatic detector detect static on clothing or hair?

A3: Yes, an electrostatic detector can detect static charges present on clothing or hair. When fabrics or hair strands rub against each other or other surfaces, they often accumulate electrostatic charges due to friction. A sensitive electrostatic detector can sense the presence of these charges without direct contact.

Tips: What are the limitations of this electrostatic detector?

This electrostatic field detector while useful for detecting static charges, has several limitations. It is highly sensitive to environmental factors such as humidity, dust, and temperature. Its detection range is often limited, making them less effective for distant. It cannot quantify charge magnitude precisely, only indicate presence.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.