This multi-channel fixed gas detector controller (available in 8, 16, 24, or 32 channels) is ideal for large-scale gas detection networks. It records up to 1,000 alarm/fault logs and stores up to 100,000 records via SD card. Each channel’s concentration value and curve are clearly shown, supporting continuous 24-hour supervision when connected to a computer—perfect for environments requiring strict gas safety control.

Multi-Channel Signal Input

- Wall-mounted design with a 7-inch high-definition color touchscreen.

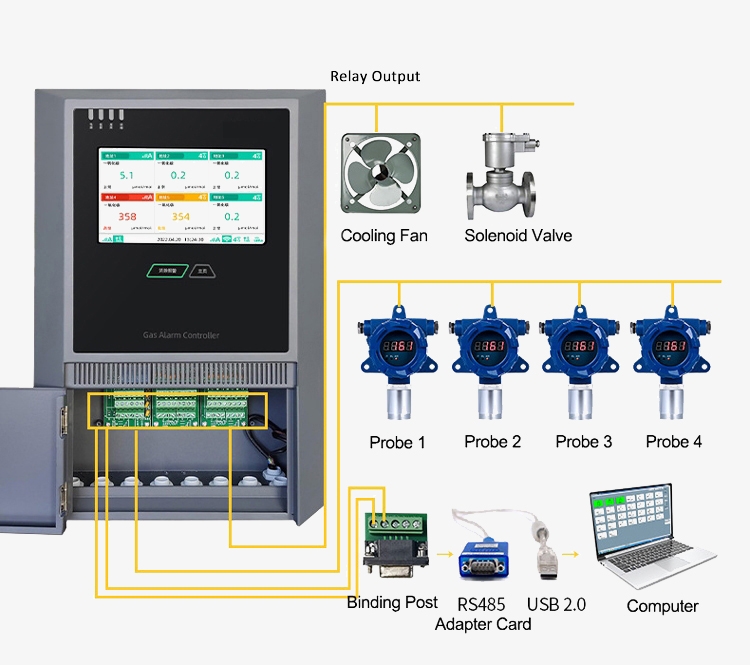

- Equipped with standard RS485 input/output, supporting 8–32 channels of 4–20mA signal input.

- This gas detector controller supports connection to a computer for 24-hour real-time monitoring through PC software, with all data automatically saved to the computer.

- Each screen can display six channels of gas concentration, including concentration values, units, and real-time curves for a single channel, providing clear and intuitive monitoring.

Large Data Storage Capacity

- The fixed gas detector controller can record 1,000 sets of alarm and fault events. A standard SD card can expand storage capacity to 100,000 sets for easy historical tracking.

- Suitable for monitoring single or multiple detectors, enabling centralized management of multiple points and effectively preventing gas leakage, explosion, and poisoning hazards.

- SISCO gas detector controller supports one-key switching between Chinese and English, with additional languages available for customization to meet regional needs.

Applications

Fixed gas detector controller is used to monitor and manage signals from fixed gas detectors, providing continuous detection of hazardous gases. It is widely applied in chemical plants, pharmaceutical factories, laboratories, oil and gas facilities, warehouses, power plants, and other industrial and commercial environments.

Laboratory

Petroleum

Pharmaceutica

Chemical

| Model | GD900-8C/16C/24C/32C |

| Matched Detector | GD300 & GD700 Series |

| Installation Method | Wall-Mounted |

| Display | 7-inch 800*480 Touch Color Screen |

| Display Mode | Adaptive Display Channel Number, Automatic Page Turning |

| Inspection Interval | 200ms (Data Collection Time Interval) |

| Communication Rate | 9600bps (Customizable) |

| Signal Input | RS485, 4-20mA |

| Input Channel (Optional) | RS485 (Default)/8/16/24/32 Channels |

| Power Input | 100~240V AC |

| Power Output | DC 24V, 0.25A/Channel |

| Working Temperature | -10C ~ 50℃ |

| Working Humidity | ≤95%RH, No Condensation |

| Accessories (Optional) | RS485 to USB Module + PC Software |

| Dimension | 464x280x100mm |

| Weight | 4.7kg |

Input Channel Selection

| Input Channel | Signal Input | Signal Output |

| N/A | RS485 | RS485 |

| 8 Channel | RS485 + 8 Groups of 4-20mA | RS485 |

| 16 Channel | RS485 + 16 Groups of 4-20mA | RS485 |

| 24 Channel | RS485 + 24 Groups of 4-20mA | RS485 |

| 32 Channel | RS485 + 32 Groups of 4-20mA | RS485 |

Details

Gas Detector Catalog & User Manual

Fixed Gas Detector GD900-8C/16C/24C/32C Controller User Manual

Fixed Gas Detector GD900-8C/16C/24C/32C Controller User Manual Fixed Gas Detector GD900-1C/2C/4C Controller User Manual

Fixed Gas Detector GD900-1C/2C/4C Controller User Manual SISCO Gas Detector Catalogue

SISCO Gas Detector Catalogue SISCO GD200 Portable Gas Detector User Manual

SISCO GD200 Portable Gas Detector User Manual SISCO GD300 Online Fixed Gas Detector User Manual

SISCO GD300 Online Fixed Gas Detector User Manual SISCO GD400 Explosion Proof Portable Gas Detector User Manual

SISCO GD400 Explosion Proof Portable Gas Detector User Manual SISCO GD500 Handheld Multi Gas Detector User Manual

SISCO GD500 Handheld Multi Gas Detector User Manual SISCO GD600 Multi Gas Analyzers User Manual

SISCO GD600 Multi Gas Analyzers User Manual SISCO Gas Detector Communication Protocol V1.0

SISCO Gas Detector Communication Protocol V1.0 SISCO Single Stage Pressure Regulator User Manual

SISCO Single Stage Pressure Regulator User Manual SISCO Gas Detector Data Downloading Operation Instruction

SISCO Gas Detector Data Downloading Operation Instruction

Q1: What is a fixed gas detector controller used for?

A1: A fixed gas detector controller is used to centrally monitor and manage signals from multiple fixed gas detectors. It processes gas concentration data, triggers audible and visual alarms, and helps ensure timely response to gas leaks in industrial and commercial environments.

Q2: How many gas detectors can the controller connect to?

A2: The controller can typically connect to multiple fixed gas detectors, depending on the model and configuration. It supports single-point or multi-channel inputs, making it suitable for both small installations and large centralized gas monitoring systems.

Q3: What types of gas detectors are compatible with the controller?

Q4: The fixed gas detector controller is compatible with various gas detectors for combustible, toxic, and oxygen gases. It usually supports standard output signals such as 4–20 mA, RS485, or relay outputs for flexible system integration.

Tips: Can the fixed gas detector controller be integrated into an existing safety system?

Yes, the fixed gas detector controller can be integrated into existing safety or automation systems through standard signal outputs and communication protocols, such as 4–20 mA, RS485, or relay outputs. This allows seamless connection with building management systems (BMS), distributed control systems (DCS), and centralized control rooms for enhanced monitoring and safety management.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.