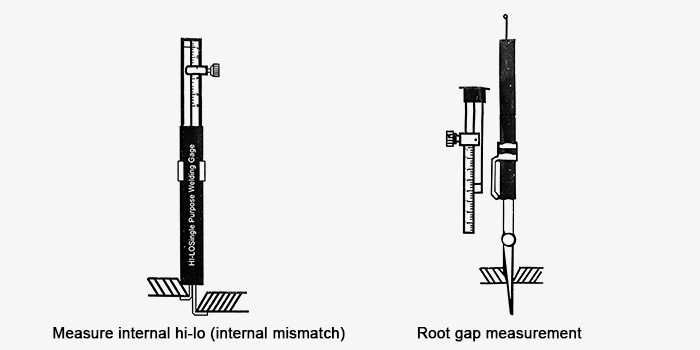

This mini hi-lo welding gauge is a professional inspection tool specifically designed for measuring internal misalignment and offset in pipe joints and weld seams. It allows users to detect pipe end mismatch before and after welding, check alignment accuracy along the seam, and measure crown height after welding. The compact hi-lo welding gauge is highly suitable for verifying precision after X-ray testing and for measuring internal gaps during pipe assembly and installation.

Precision-Forged Steel, Accuracy You Can Trust

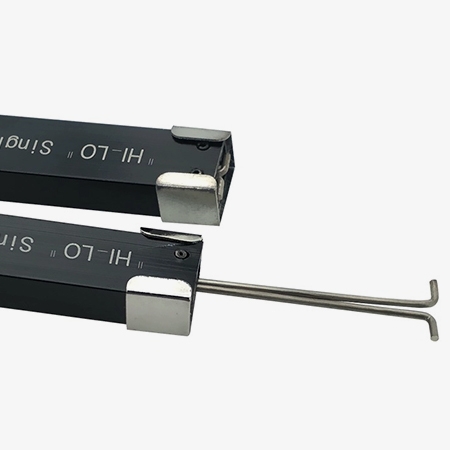

- This hi-lo single-purpose welding gauge is forged from thickened stainless steel for outstanding durability and resistance to wear, ensuring long-term performance in industrial environments.

- Built to Grade 1 precision standards, the small hi-lo gauge guarantees consistent accuracy that complies with international welding measurement standards.

Adjustable Locking Mechanism, Multi-Functionality in One Gauge

- Equipped with a tightening nut, the compact hi-lo welding gauge allows users to easily adjust and lock the measuring arm for stable and repeatable readings.

- This versatile weld measuring tool not only checks for joint gap misalignment, but also accurately measures weld reinforcement height and thickness, supporting multiple inspection tasks with a single instrument.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

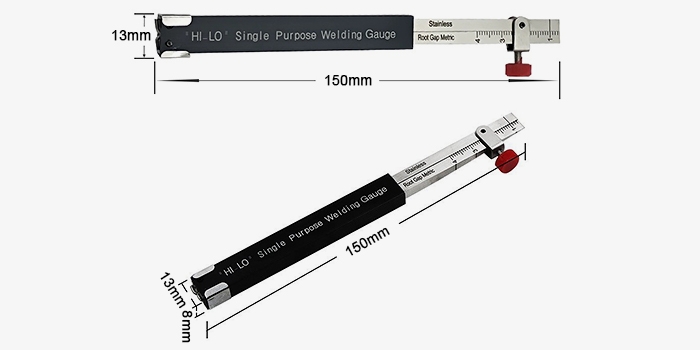

| Model | SISCO-WG-HLSP |

| Material | Stainless Steel |

| Measuring Range | 0.5~4cm |

| Product Dimensions | 150×13(mm) |

| Scale Marking | Laser-engraved graduations |

| Net Weight | 57g |

| Application | Suitable for welding inspection and measurement in boiler fabrication, shipbuilding, bridge construction, pressure vessels, and pipeline welding projects. |

Details

Q1: What are the main applications of this hi-lo single-purpose welding gauge?

A1: This compact hi-lo welding gauge is specifically designed for welding inspection tasks. It accurately measures internal misalignment (hi-lo offset), root gap, and joint fit-up discrepancies. Ideal for both pre-weld and post-weld inspection, it is widely used in boiler manufacturing, shipbuilding, steel structures, and oil pipeline construction—ensuring precise alignment and improved structural safety.

Q2: What working environments is this small hi-lo gauge suitable for?

A2: Constructed from high-grade stainless steel with laser-engraved graduations, this weld gauge performs reliably in harsh industrial environments. Whether exposed to moisture, oil, or confined spaces, it maintains high readability and stability, making it perfect for field welding inspection and daily quality control applications.

Q3: Is the locking nut fixed on the gauge? How can I adjust it?

A3: This hi-lo gauge features an adjustable locking nut, allowing users to manually control the tension according to their measurement needs. The nut can be tightened or loosened easily by hand, without tools, ensuring a secure and efficient measuring experience—especially useful in elevated or uneven work areas.

Tips: What should I pay attention to when using a hi-lo welding gauge?

- Before use, make sure the gauge surface is clean and free of oil to avoid affecting measurement accuracy.

- During measurement, operate smoothly and avoid sudden drops or impacts to maintain precision.

- If not in use for an extended period, store it in a dry environment and wipe it regularly to prevent rust.

- When tightening the locking nut, apply moderate force—too loose or too tight may lead to inaccurate readings or damage to components.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.