Multi-function mini clamp meter for sale, for measuring AC/DC current 0-600A, AC/DC voltage 0-600V, LED backlight display and easy to read, support data hold, fine jaw structure design, good measurement repeatability.

Data hold key

- Used to lock the current measurement value.

- When the real-time value needs to be maintained, press the HOLD key to judge and record.

- Function range knob, accurate gear.

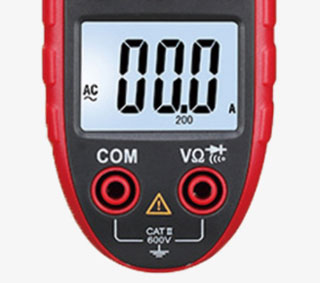

LED display

- Display high-definition backlight, low voltage display.

- Wear-resistant silicone case for long service life.

- Pen socket, is smooth and stable.

Application

The clamp meter is one of the necessary test tools in daily maintenance work, mainly used to test voltage, current, frequency and other related parameters, requiring its high test resolution, test accuracy, and more test functions. Applications mainly include industrial control, industrial equipment, commercial, industrial, and residential electrical systems, and HVAC.

| Basics | Model | SISCO-UA3268D | |

| Weight | 160g | ||

| Size (L*W*H) | 185*51*25mm | ||

| Display | 4 digit LCD display | ||

| Maximum display value | 5999 | ||

| Power supply | DC 3V, 2 AAA batteries | ||

| Maximum jaw opening size | 28mm | ||

| Woring environment | Temperature: 5℃~35℃ (41℉~95℉), relative humidity:<75% | ||

| Storage temperature | -10℃~+50℃ (14℉~122℉) | ||

| Accessories | A pair of test probes, a pair of temperature probes, a user manual, 2 AAA batteries | ||

| Functions | Item | Range | Accuracy |

| DC current | 600A | ±(2.0%+10 digits) | |

| AC current | 600A | ±(2.0%+10 digits) | |

| Inrush current | 600A | ±(2.0%+10 digits) | |

| DC voltage | 600V | ±(0.8%+5 digits) | |

| AC voltage | 600V | ±(1.2%+5 digits) | |

| Resistance | 60MΩ | ±(0.8%+3 digits) | |

| Frequency | 10MHz | ±(0.5%+3 digits) | |

| Capacitance | 100mF | ±(3.0%+5 digits) | |

| Temperature | -50℃~+1000℃ (-58℉~1832℉) | ±(1.0%+4 digits) | |

| Special functions | TRMS | True RMS measurement for sine wave signal | |

| Diode test | Display forward voltage value of diode | ||

| On-off buzzer | Continuity test buzzer | ||

| Data hold | Hold the reading when taking a measurement | ||

| Automatic power off | Automatic power off when 15 minutes no operation | ||

| Overload protection | Overload protection for 100% range | ||

| Range selection | Automatic range selection and manual range selection | ||

| Backlight | Backlight for LCD display | ||

| Inspection light | Inspection light for clamp operation | ||

Q1: What is a clamp meter?

A1: A clamp meter is a device used to measure current conveniently and safely. It is very efficient to measure current without using test leads. To measure

current, all you have to do is place a wire in the jaws of the clamp meter. When current flows through a conductor, a magnetic field is created. The device helps to detect magnetic fields so that it can provide corresponding current readings, the sisco clamp meter can also be used as a multimeter.

Q2: How a clamp meter works?

A2: Clamp meters work on the principle of magnetic induction and measure alternating current without contact. Like every conductor, the current flowing

through the wire creates a magnetic field. Hall effect sensors detect the magnetic field produced by the current, which in turn creates a small voltage

across the sensor.

Q3: How often does a clamp meter need to be calibrated?

A3: A clamp meter typically needs to be calibrated annually to ensure it continues to measure within sisco's specifications.

Tips: The difference between a clamp meter and a digital multimeter

In the industrial production process, some low-voltage equipment or circuits that are running need to know the current situation at any time, but the equipment must run continuously. In order not to affect the production or bring unnecessary losses, it is impossible to connect the digital multimeter to the equipment in series after power failure and then measure the current in the circuit. Therefore, in order to measure the current without cutting the circuit, a clamp meter was developed based on the basic digital multimeter. Although it is not as accurate as a multimeter, it provides a valid reference standard for maintenance personnel. Moreover, it is easy and convenient to operate. Therefore, the difference between a clamp meter and a digital multimeter is the way to measure current. Clamp meter can directly measure the current in the line, just press the trigger to open the jaws, and put the single line to be measured in the middle of the jaws without disconnecting the power line. And ordinary digital multimeter to measure the current, the multimeter's black and red pointer in series must be connected in series with the power line.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.