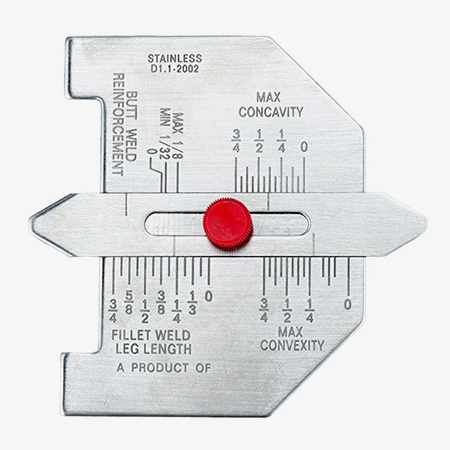

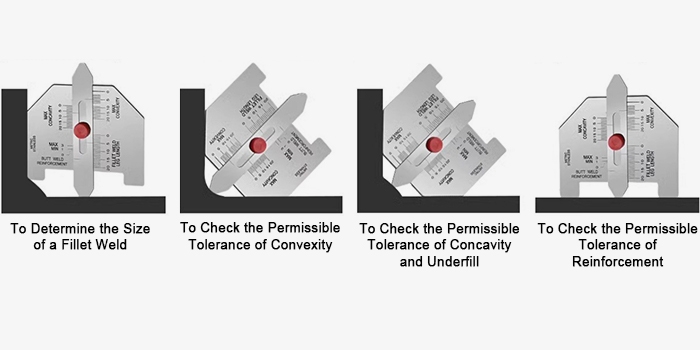

Specially designed for welding quality control, this fillet weld gauge is ideal for inspecting both butt and fillet welds. It accurately measures reinforcement height and precisely evaluates throat depth to determine weld leg size. Built from corrosion-resistant stainless steel, the fillet gauge is perfectly suited for applications with strict welding standards, such as boilers and pressure vessels.

Premium Materials for Long-lasting Performance

- The SISCO fillet weld gauge is manufactured using thickened stainless steel, offering exceptional wear resistance and durability even under harsh working environments.

- Each unit undergoes rigorous quality control checks to ensure that the fillet gauge meets industry-grade performance standards, providing welders with a dependable and consistent measuring experience.

Precision Laser Markings & Versatile Applications

- Equipped with laser-etched scales, the welding gauge delivers sharp and readable measurements that minimize human error caused by unclear markings.

- This weld fillet gauge is ideal for use in shipbuilding, bridge construction, pressure vessels, and other industrial welding applications, meeting diverse inspection needs across various sectors.

Applications

Weld gauges are widely used in various industries. In boiler manufacturing, they measure weld reinforcement, width, misalignment, and undercut depth to meet pressure part standards. In shipbuilding, they check fillet weld size, leg height, and assembly gaps to ensure hull strength. In oil pipelines, welding gauges assess groove angles and gap sizes to prevent welding defects and leaks. In industrial construction—such as bridges and pressure vessels—they provide accurate weld dimension data for process evaluation and quality control.

Shipbuilding

Oil Pipelines

Industrial Construction

Boiler Manufacturing

| Model | SISCO-WG-HG-008 |

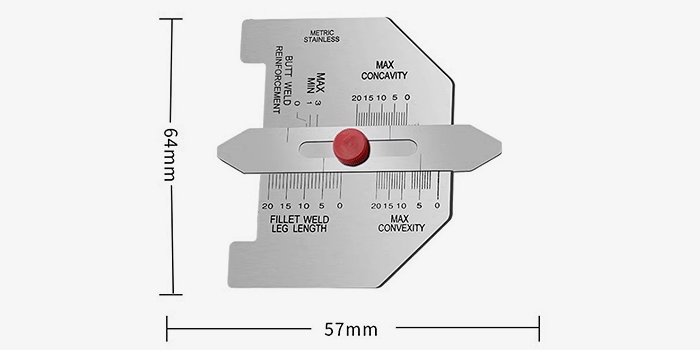

| Measuring Range | 0–20 mm (Metric) / 0–30 mm (Imperial) |

| Accuracy | ±0.5 |

| Dimensions | 64×57 (mm) |

| Material | Stainless Steel |

| Scale Type | Laser-Engraved |

| Packaging | Leather Case |

| Net Weight | 75g |

Details

Q1: What can the SISCO fillet weld gauge measure?

A1: The SISCO fillet gauge is designed to measure critical weld parameters, including fillet weld throat depth, reinforcement height, and groove angles. It is suitable for both butt and fillet welds and helps ensure that welding joints comply with international standards in industries like shipbuilding, boiler manufacturing, and pressure vessel fabrication.

Q2: Is this fillet weld gauge available in both metric and imperial units?

A2: Yes, this weld measuring gauge is available in dual-unit versions. You can choose between metric (0–20mm) or imperial (0–30mm) measurement scales based on your project requirements. The easy-to-read laser-engraved scale ensures accurate results in either system.

Q3: What material is used, and how durable is the gauge?

A3: The weld fillet gauge is constructed from premium stainless steel, offering excellent corrosion resistance and long-term durability. It is engineered to withstand heavy usage in industrial environments, making it a reliable tool for professional weld inspections.

Tips: How do you maintain a fillet weld gauge for long-term accuracy?

To keep your fillet weld gauge accurate and in good condition:

- Clean it regularly with a dry cloth or a bit of isopropyl alcohol. Avoid corrosive solvents like acetone.

- Store it in the included leather pouch to prevent scratches or damage.

- Avoid dropping or applying excessive force, as it may compromise scale accuracy.

- After working in humid or dusty environments, wipe it down to prevent buildup and corrosion.

Proper maintenance not only extends the lifespan of your gauge but also ensures consistent weld measurement accuracy on every job.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.