Pressure gauge refers to the elastic element as the sensitive element, measuring and indicating higher than the ambient pressure of the instrument, the application is extremely common, it is almost all industrial processes and scientific research fields. In the heat pipe network, oil and gas transmission, water supply and gas supply system, vehicle maintenance workshop and other fields can be found everywhere.

Especially in the industrial process control and technical measurement process, the mechanical pressure gauge of the elastic sensitive element has high mechanical strength as well as production convenience and other characteristics, so the pressure gauge has been more and more widely used.

Working Principle of Pressure Gauge

Pressure gauge through the table of sensitive components (bourdon tube, membrane box, bellows) of the elastic deformation, and then by the table movement of the conversion mechanism will be the pressure deformation conduction to the pointer, caused by the pointer to rotate to display the pressure.

The Main Structure of the Pressure Gauge

- Overflow Hole: In case of an emergency situation where the bourdon tube bursts, the internal pressure will be released to the outside world through the overflow hole to prevent the glass panel from bursting. To maintain proper performance of the overflow orifice, a space of at least 10 mm must be left behind the pressure gauge and the overflow orifice must not be altered or blocked.

- Pointers: Pointers other than standard pointers are optional.

- Glass Panel: In addition to the standard glass, other special glass materials, such as reinforced glass and non-reflective glass, are also available.

Classification of Pressure Gauge

According to the measurement accuracy, pressure gauges can be divided into precision pressure gauges and ordinary pressure gauges. The measurement accuracy levels of precision pressure gauges are 0.1, 0.16, 0.25, and 0.4 respectively, while the measurement accuracy levels of ordinary pressure gauges are 1.0, 1.6, 2.5, and 4.0 respectively.

Based on pressure indication standards, pressure gauges are categorized into normal, absolute, and differential pressure gauges. Normal pressure gauges are based on atmospheric pressure, absolute pressure gauges are based on zero absolute pressure, and differential pressure gauges measure the difference between two measured pressures.

Based on the measurement range they are categorized as vacuum gauges, pressure vacuum gauges, micro pressure gauges, low-pressure gauges, medium-pressure gauges, and high-pressure gauges. Vacuum gauges are used to measure pressure values less than atmospheric pressure.Pressure vacuum gauges are used to measure pressure values less than or greater than atmospheric pressure. Micro-pressure gauges are used to measure pressure values less than 60,000 Pa.

Low-pressure gauges are used to measure pressure values from 0 to 6 MPa. For example, 0 to 100 psi Pressure Gauge, 0~7 bar, 0 to 300 psi Pressure Gauge, 0~20 bar, etc. They can be widely used in the industries of chemical, petroleum, metallurgy, mining, and electric power production, ect.

Medium pressure gauges are used to measure pressure values from 10 to 60 MPa. High-pressure gauges are used to measure pressure values above 100 MPa. Shock pressure gauges have completely sealed housings with damped flow paths, which, due to their damping effect, can be used in places where the working environment is vibrating or where medium-pressure (load) measurements are made. Pressure gauges with electrical contact control switches allow signaling alarm or control functions.

Pressure gauges with remote transmission mechanisms can provide electrical signals (e.g. resistance signals or standard DC current signals) required for industrial engineering. Isolators (chemical seals) used in diaphragm gauges separate the measured medium from the instrument by means of an insulating diaphragm, which can measure the pressure of media with strong corrosive, high temperature, and easily crystallizable properties.

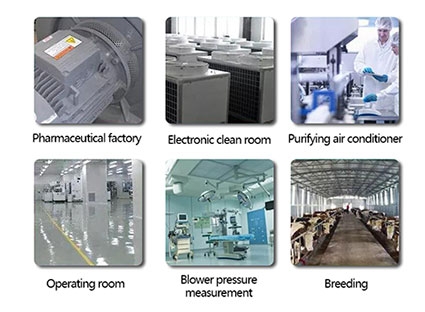

Applications

Pressure gauge is the most commonly used measuring instrument for displaying and controlling pressure. The pressure gauges are widely used in the chemical industry, petroleum, metallurgy, mining, and electric power production, especially in vehicle maintenance shops, heat pipe networks, water and gas supply systems, etc.

I hope that with this information, you can understand more about what is a pressure gauge. sisco.com offers high precision, high quality pressure gauges, click to shop if you are interested.