The microplate reader absorbance supports touchscreen visualization for plate placement and template import, and has a built-in data storage capacity of 200,000 records and a quality control module to ensure reliable and traceable test results.

Broad-spectrum, High-speed Detection

- The plate reader absorbance supports four measurement modes: single-wavelength, dual-wavelength, two-point, and kinetic. The wavelength coverage is 405~630 nm, and the absorbance measurement range is 0.000~4.000 A, with reliable accuracy.

- Three analysis modes are available: absorbance mode, qualitative mode, and quantitative mode. The quantitative mode includes various curve-fitting methods and is suitable for a variety of ELISA assays.

- The 8-channel design enables rapid and efficient experimental result acquisition with single-wavelength detection speeds of less than 3 seconds and dual-wavelength detection speeds of less than 6 seconds.

Intelligent Calibration and Convenient Output

- Compatible with 96-well visual microplates, allowing flexible well placement and supporting parallel detection of 12 different items on the same plate. It also supports template import and batch plate placement for easy operation.

- The ARM core system can store 200,000 detection data entries and supports searching by sample number, detection date, and other criteria. Equipped with a built-in thermal printer, it supports external USB printers of specified models and can output synthesis reports and graphs.

- The absorbance reader supports single-point or multi-point standard curve calibration (2~8 standards), automatically checking the monotonicity of concentration values. It will prompt an error if abnormal absorbance of the standards is detected (such as deviation in repeatability or out-of-range).

Applications

Microplate readers are core equipment for quantitative detection in multiple fields. In clinical diagnosis, they detect antigens and antibodies in serum and urine, aiding in the screening of diseases such as hepatitis and tumor markers. In biopharmaceutical research and development, they are used for drug activity evaluation and cytotoxicity detection, supporting new drug development. In food safety testing, they rapidly determine pesticide, veterinary drug residues, and microbial toxins. In animal and plant quarantine, they detect pathogens and antibodies in body fluids to prevent the spread of diseases.

Biomedical Research

Food Safety Monitoring

Animal Quarantine

Clinical Diagnosis

| Model | SISCO-AMR-DK3518 |

| Light Source | Quartz halogen lamp OSRAM64607, 8V/50W or LED Light |

| Wavelength | 405nm, 450nm, 492nm, 630nm, 4 more filter positions can be installed with wavelength between 400~800 nm(Halogen lamp), or 400~720nm (LED light) |

| Measuring Range | 0.000~4.000A |

| Reading Speed | Single Wavelength≤3s, Double Wavelength ≤6s |

| Warm-up Time | 10 minutes |

| Computer System | ARM core series |

| Programming Items | More than 500 |

| Communication Interface | RS-232 serial, Parallel printer, USB, Mouse, and keyboard interface |

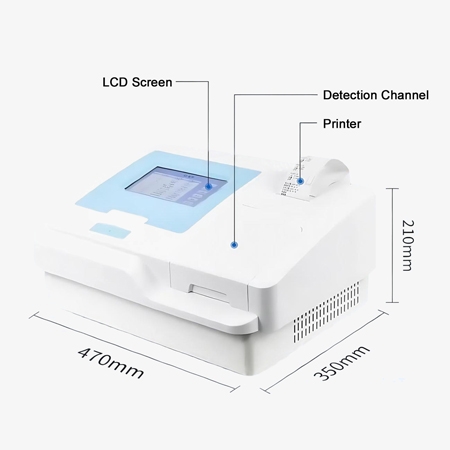

| Display | LCD display screen |

| Input Mode | Touch Screen, Touch pen |

| Memory Capability | 200,000 test data |

| Net Weight | 8 kg |

| Dimension | 475mm×340mm×200mm |

| Power Supply | AC 100V~240V, 50/60 Hz |

| Working Environment | Environment temperature: +5℃~+40℃℃ |

| Relative humidity: 15%~80% | |

| Atmospheric range: 70kPa~106kPa | |

| Power supply: AC 100V~240V,50/60 Hz | |

| Transient over-voltage is classified as device class (over-voltage) class II | |

| Rating pollution level is classified as class II | |

| Storage Temperature | -10℃~+55℃ |

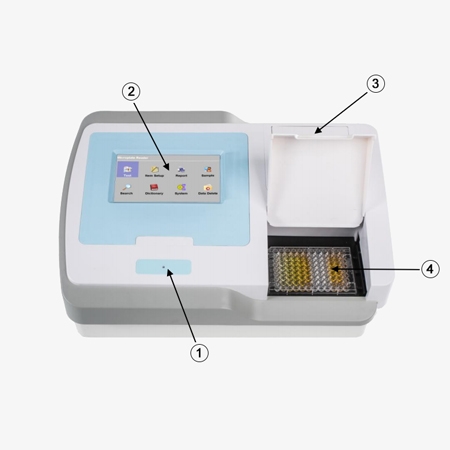

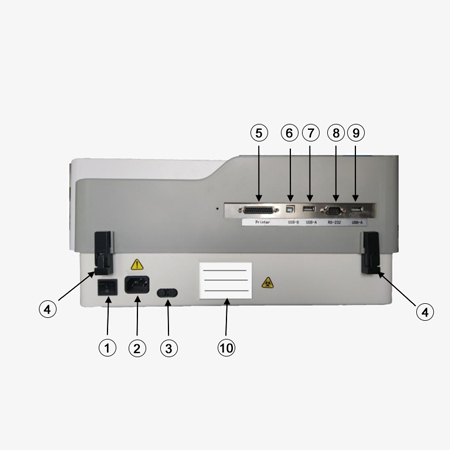

Structural diagram

- Power switch: Turn on or turn off the power supply.

- Power cord socket: Connect the AC power cord.

- Fuses: If no power after turning on the power supply switch, check the fuses.

- Hinges: Connect the bottom shell and the top cover.

- Parallel port: It is used for connecting a parallel printer.

- USB-B interface: It is used for connecting a PC computer.

- USB-A interface: It is used for connecting the mouse & keyboard.

- RS-232 Serial port: It is used for connecting PC computer.

- USB-A interface: It is used for updating the motherboard firmware.

- Nameplate: Show instrument model, specification, etc.

Q1: What is the difference between absorbance, fluorescence, and luminescence microplate readers?

A1: Absorbance, fluorescence, and luminescence microplate readers differ mainly in their detection principles. An absorbance reader measures how much light a sample absorbs and is commonly used for ELISA and OD600. A fluorescence reader uses an excitation light source and detects the emitted fluorescence, offering higher sensitivity for DNA, protein, and cell-based assays. A luminescence reader measures light produced directly by chemical or biological reactions without excitation light, providing the highest sensitivity for assays such as ATP and luciferase.

Q2: What is the wavelength range of a microplate reader?

A2: The wavelength range of a microplate reader depends on the detection mode, but most absorbance readers cover approximately 200–1000 nm for UV-Vis measurements, while fluorescence readers use specific excitation and emission ranges set by filters or a monochromator, and luminescence readers typically do not require wavelength selection because they detect total emitted light.

Q3: How fast can a microplate reader read a full plate?

A3: The reading speed of a microplate reader varies by model and detection mode, but most instruments can read a full 96-well plate in just a few seconds for absorbance, typically 5–10 seconds for fluorescence, and slightly longer for luminescence, depending on integration time. High-performance systems can read even faster, especially in endpoint measurements.

Tips: What samples can be measured with a Microplate Reader?

- Protein and nucleic acid quantification.

- Enzyme activity assays.

- ELISA and immunological assays.

- Cell proliferation and cytotoxicity assays.

- Fluorescent or luminescent reporter gene assays.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.