This inductive displacement transducer is a cost-effective displacement measurement tool that combines environmental adaptability, ease of installation, and operational flexibility, making it an ideal choice for replacing traditional complex solutions and upgrading existing equipment.

Multifunctional Adaptability

- The displacement transducer supports measurement direction setting, scaling factor correction, and initial value presetting. This means you can easily set any point as the zero point, compensate for mechanical system errors, or display values in reverse, significantly improving the efficiency of equipment installation and debugging.

- The system accuracy reaches ±(0.05+0.02*L) mm, with a maximum repeatability of ±0.01mm, and supports three resolution settings: 0.01, 0.1, and 1.

- The displacement detector features a convenient built-in self-calibration function. Simply move the reading head along the magnetic strip at a low, constant speed, and the device will automatically complete the accuracy calibration. It also allows setting the automatic LCD backlight off time, ensuring intelligent management for accurate and energy-efficient measurement.

Low Power Consumption for Multiple Scenarios

- The displacement measurement transducer not only allows for quick switching between millimeters and inches but also features an angle measurement mode. By setting the diameter of the disc to which the magnetic strip is attached, the rotation angle can be directly displayed, easily handling both linear displacement and angle measurement needs.

- A 7-digit LCD provides a wide display range, suitable for the precise measurement requirements of long-stroke equipment. The reading head movement speed reaches 3m/s, with a maximum gap of 1.5mm.

- Battery-powered with extremely low power consumption (≤600μA), it achieves true plug-and-play functionality, making it particularly suitable for field operations, mobile equipment, or situations without a fixed power supply.

Applications

Displacement sensors are indispensable in four core areas: first, industrial automation, used for precise positioning and control of robots and production lines; second, precision detection and measurement, ensuring workpiece dimensions and processing quality; third, scientific research, supporting precision experiments in materials and micro-nano fields; and finally, equipment health and safety monitoring, monitoring the deformation and vibration of key structures in real time to prevent failures.

Precision Testing

Scientific Research

Equipment Safety

Industrial Automation

| Model | SISCO-DS-SWLDS30A |

| System Accuracy | Tolerance (0.05 + 0.02*L)mm L unit: meters |

| Repeatability | Max. tolerance: 0.01 mm |

| Resolution | 0.01, 0.1, 1 |

| Display Range | -199999~99999 |

| Current Consumption | ≤600μA |

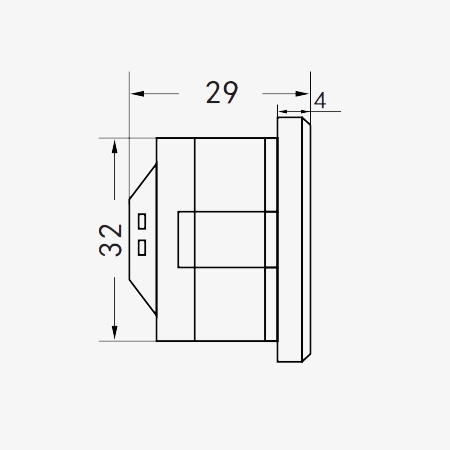

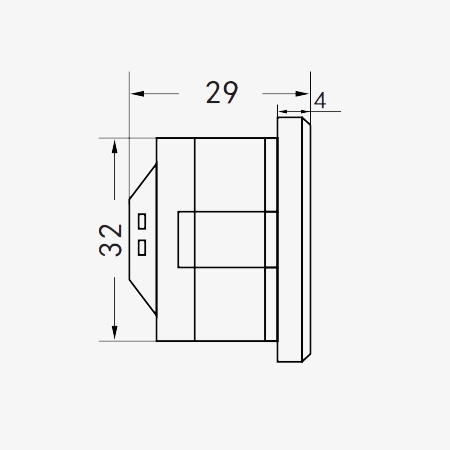

| Maximum Overall Dimensions | 74mm×36mm×32mm |

| Mounting Hole Dimensions | 67mm×32mm |

| Readhead Cable Length | Default 1M (customizable) |

| Readhead Gap | Max.1.5mm |

| Moving Speed | Max.3m/s |

| Waterproof Rating | Digital display meter: IP40, reading head: IP67 |

| Operating Temperature | -10℃~+60℃ |

| Storage Temperature | -20℃~+70℃ |

| Weight | 97g(With a reading head) |

Structural diagram

Q1: What Is Linear Displacement?

A1: Linear displacement refers to the change in position of an object along a straight line, and its movement is usually quantified by measuring the distance from the starting point to the ending point. In industrial applications, accurate measurement of linear displacement is crucial for controlling mechanical motion, positioning, and monitoring.

Q2: How to Reduce Measurement Noise in Displacement Sensors?

A2: To reduce measurement noise, ensure that the steel cable is installed horizontally (deviation ≤ ±3°), keep the pulleys clean, and avoid dust accumulation; install protective devices in harsh environments, and connect the circuit correctly (e.g., connect the load before powering on) to reduce mechanical and electromagnetic interference.

Q3: How to Maintain a Displacement Sensor for Long-Term Accuracy?

A3: To maintain the long-term accuracy of general displacement sensors: ensure stress-free installation and avoid exceeding the range or harsh environments; regularly clean the probe and contact surface, check for wear on mechanical parts, and calibrate data on time.

Tips: How Do You Calibrate a Displacement Sensor?

To calibrate a displacement sensor, first clean the sensor probe and the reference surface being measured, ensuring secure installation and alignment of the axis with the displacement direction.Then, select a standard component with known accuracy and choose multiple evenly distributed calibration points within the sensor's full measurement range. Use the displacement values set on the standard component as references, record the sensor's output signal, and compare the output value with the reference value to calculate the error.

Eliminate deviations by adjusting parameters using the sensor's built-in calibration program or an external controller. Repeat the calibration process until the error at each calibration point is within the allowable range. Finally, record the calibration data and periodically recalibrate to ensure accuracy.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.