The linear displacement transducer features rich signal output modes, flexibly adapting to different industrial control systems, providing users with a stable, efficient, and flexible displacement measurement and position control solution.

High Precision, Multi-Range

- The linear displacement transducer sensor boasts a linear accuracy of up to 0.25% (optional 0.1%), providing accurate linear displacement measurement, suitable for scenarios requiring high-precision positioning and control.

- The stroke range is from 100mm to 1000mm, meeting the stroke length requirements of various applications, such as warehouse positioning and gate opening control.

- The displacement measurement devices support multiple signal types, including resistance signals, analog current signals, analog voltage signals, pulse signals, and digital outputs, facilitating connection and integration with various control systems.

High Durability and Strong Protection

- The displacement detector features a miniaturized design, combining the advantages of angle and linear displacement sensing. It requires minimal installation space, supports threaded connections and base plate mounting, and is suitable for space-constrained applications.

- The default gauge for steel wire rope is 0.8mm. A service life of up to 3 million cycles is available, suitable for high-frequency, long-term operation equipment such as mechanical positioning and gate control.

- With an IP65 protection rating, it is suitable for ambient temperatures from -20℃ to 80℃ and offers customized options such as dustproof, waterproof, and magnetic attachment, making it suitable for humid, dusty, or high-vibration industrial environments.

Applications

Displacement sensors are indispensable in four core areas: first, industrial automation, used for precise positioning and control of robots and production lines; second, precision detection and measurement, ensuring workpiece dimensions and processing quality; third, scientific research, supporting precision experiments in materials and micro-nano fields; and finally, equipment health and safety monitoring, monitoring the deformation and vibration of key structures in real time to prevent failures.

Precision Testing

Scientific Research

Equipment Safety

Industrial Automation

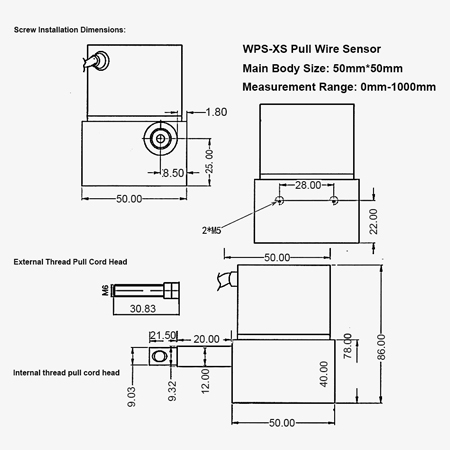

| Model | SISCO-DS-WPSXSA2 |

| Measuring Range | 100~1000mm |

| Linear Accuracy | 0.25% (default), 0.1% |

| Wire Rope Specifications | 0.8mm (default), 0.6mm, 0.7mm |

| Electrical Connections | 1-meter cable (default) |

| Voltage | Up to 24V |

| Output Method | Resistance 5kΩ/10kΩ, Voltage 0~5V/0~10V, 4~20mA, Pulse, Digital Output |

| Ambient Temperature | -20~+80℃ |

| Protection Class | IP65 |

| Service Life | Three million cycles |

Structural Diagram

Q1: What Is Linear Displacement?

A1: Linear displacement refers to the change in position of an object along a straight line, and its movement is usually quantified by measuring the distance from the starting point to the ending point. In industrial applications, accurate measurement of linear displacement is crucial for controlling mechanical motion, positioning, and monitoring.

Q2: How to Reduce Measurement Noise in Displacement Sensors?

A2: To reduce measurement noise, ensure that the steel cable is installed horizontally (deviation ≤ ±3°), keep the pulleys clean, and avoid dust accumulation; install protective devices in harsh environments, and connect the circuit correctly (e.g., connect the load before powering on) to reduce mechanical and electromagnetic interference.

Q3: How to Maintain a Displacement Sensor for Long-Term Accuracy?

A3: To maintain the long-term accuracy of general displacement sensors: ensure stress-free installation and avoid exceeding the range or harsh environments; regularly clean the probe and contact surface, check for wear on mechanical parts, and calibrate data on time.

Tips: What Factors Affect the Accuracy of a Displacement Sensor?

Factors affecting the accuracy of displacement sensors mainly fall into three categories: environment, equipment characteristics, and installation and usage methods.

- Environmentally, temperature changes, humidity, dust, electromagnetic interference, and vibration/shock can interfere with measurements by affecting material properties, electronic components, or mechanical structures.

- The equipment itself is limited by its type and operating principle, insufficient resolution and sampling frequency, zero-point drift, temperature drift, and mechanical wear.

- During installation and use, installation deviations, incompatible characteristics of the measured object, abnormal power supply and signal transmission, and lack of standardized calibration and maintenance can all lead to decreased accuracy or measurement distortion.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.