The laser displacement transducer supports both RS232 and RS485 dual communication interfaces and multi-device networking (up to 64 units), easily integrating into industrial automation systems to meet industrial dynamic monitoring needs.

High-Precision Response

- The laser displacement gauge uses phase-shift ranging technology, achieving a measurement accuracy of ±(2mm + d × 0.01%) (where d is the actual distance). The measurement rate can be adjusted within the range of 1Hz-10Hz, providing a fast response to measurement requirements.

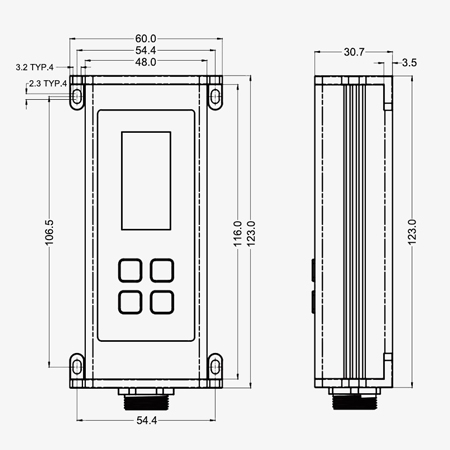

- It features a 128x64 dot matrix display screen that clearly shows measurement distance, units, and rate information; equipped with dedicated buttons supporting short and long presses, allowing convenient access to parameter settings and adjustment of operating parameters.

- The displacement transducer provides both RS232 and RS485 serial communication interfaces, allowing users to choose flexibly based on different application scenarios for data communication and networking with PLCs, industrial computers, or other host devices.

Remote Monitoring and Linkage Control

- The displacement measurement devices have a 16-bit wide function register list, allowing users to read or modify specific parameters through the communication protocol, enabling remote configuration and status monitoring of the sensor's operating mode.

- It features transistor switch output functionality, allowing connection to external relays, alarm horns, LEDs, etc., with a sink current not exceeding DC36V 0.5A, adapting to linkage control requirements in industrial scenarios.

- The displacement sensor uses a die-cast metal casing and has an IP67 protection rating, capable of withstanding harsh environmental conditions.

Applications

Displacement sensors are indispensable in four core areas: first, industrial automation, used for precise positioning and control of robots and production lines; second, precision detection and measurement, ensuring workpiece dimensions and processing quality; third, scientific research, supporting precision experiments in materials and micro-nano fields; and finally, equipment health and safety monitoring, monitoring the deformation and vibration of key structures in real time to prevent failures.

Precision Testing

Scientific Research

Equipment Safety

Industrial Automation

| Model | SISCO-DS-SWLDS30A |

| Measurement Distance | 0.2~30m |

| Voltage/Current Output | None |

| Voltage Output Error | None |

| Current Output Error | None |

| Measurement Frequency | 1Hz~20Hz |

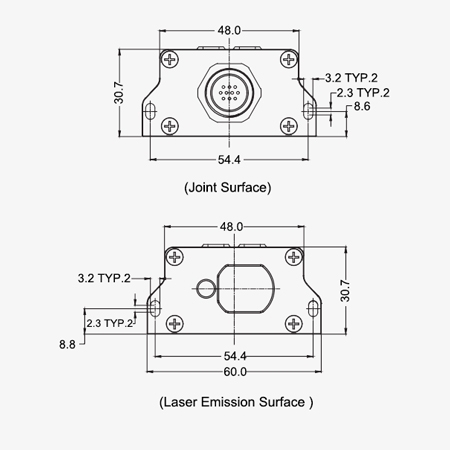

| Laser Type | 639±15nm, <1mW |

| Measurement Resolution | 1mm |

| Measurement Accuracy | ±(2mm + d*0.0001) |

| Indicator Light | Red laser |

| Display Screen | 128x64 dot matrix screen |

| Backlight Off Time | 180s |

| Operating Modes | Measurement off, Continuous measurement |

| RS485 Interface | Yes |

| RS232 Interface | Yes |

| Transistor Switching Output | 1 channel (cannot exceed DC 36V 0.5A) transistor switch output for external DC; exceeding the specified voltage or current may cause permanent damage to the instrument. |

| Power Supply | 3 DC 15~26V |

| Power Consumption | <3.0W |

| Protection Class | IP67 |

| Housing Material | Die-cast aluminum alloy |

| Operating Temperature | -10°C~+50°C |

| Storage Temperature and Humidity | -20°C~+60°C, 20%~85%RH |

| Overheat Protection | Measurement shuts off when body temperature exceeds 70°C, and resumes when below 70°C. |

| Dimensions | 123mmx60mmx30.7mm (excluding connector) |

Structural Diagram

Q1: What Is Linear Displacement?

A1: Linear displacement refers to the change in position of an object along a straight line, and its movement is usually quantified by measuring the distance from the starting point to the ending point. In industrial applications, accurate measurement of linear displacement is crucial for controlling mechanical motion, positioning, and monitoring.

Q2: How to Reduce Measurement Noise in Displacement Sensors?

A2: To reduce measurement noise, ensure that the steel cable is installed horizontally (deviation ≤ ±3°), keep the pulleys clean, and avoid dust accumulation; install protective devices in harsh environments, and connect the circuit correctly (e.g., connect the load before powering on) to reduce mechanical and electromagnetic interference.

Q3: How to Maintain a Displacement Sensor for Long-Term Accuracy?

A3: To maintain the long-term accuracy of general displacement sensors: ensure stress-free installation and avoid exceeding the range or harsh environments; regularly clean the probe and contact surface, check for wear on mechanical parts, and calibrate data on time.

Tips: What Should I Do If My Laser Displacement Sensor Can't Detect the Target?

If the laser displacement sensor fails to detect the target, follow these steps to troubleshoot:

- First, check if the power supply and wiring are normal and if the sensor is in a ready-to-use state.

- Then, confirm that the installation distance is within its calibrated effective measurement range and adjust the sensor angle so that the laser beam is perpendicular to the surface being measured.

- Next, clean the dust from the sensor lens and the surface of the target being measured.

- If necessary, restore the sensor to factory settings and recalibrate it. If it still cannot detect, check for sensor hardware failure or contact after-sales service for repair.

Thank you for buying industrial test and measurement equipment on SISCO.com, all products sold by SISCO and the partner cover a 12 months warranty, effective from the date of receiving the products.

What is covered?

SISCO is responsible for providing free spare parts, and free technical support to assist the customer to repair the defective products until the problem is solved.

What is not covered?

- Product purchased from anyone other than a SISCO store or a SISCO authorized reseller.

- Expendable parts.

- Routine cleaning or normal cosmetic and mechanical wear.

- Damage from misuse, abuse or neglect.

- Damage from use of parts other than SISCO approved.

- Damage from use outside the product’s usage or storage parameters.

- Damage from use of parts not sold by SISCO.

- Damage from modification or incorporation into other products.

- Damage from repair or replacement of warranted parts by a service provider other than a SISCO authorized service provider.

- Damage caused by the application environment not meeting the product usage requirements and the failure to perform preventive maintenance.