In scenarios such as industrial production, scientific research experiments, and medical operations, eye protection is a crucial link in ensuring personal safety. Safety goggles and safety glasses, as two common types of protective equipment, are often confused and used interchangeably, but there are essential differences between them in terms of protective capabilities, design logic, and applicable scenarios. Making the wrong choice will not only reduce the protective effect but may also cause eye injury accidents. This blog will compare them from three major dimensions: protection range, applicable scenarioss, and tructural design to provide purchasing suggestions to help readers accurately match their protection needs.

Essential Difference: Protection Range

The risk of eye injuries does not only come from the front; liquid splashes, dust intrusion, or droplet contact from the sides and above are also significant hazards. In a chemical laboratory, when concentrated sulfuric acid is accidentally spilled, if only ordinary safety glasses are worn, the splashing acid can easily seep in from the sides and burn the eyes. In construction scenarios, sharp debris generated from grinding stones may fall from above and pierce the skin around the eyes. The core difference between safety goggles and safety glasses first lies in the extent of coverage of their protection range.

Safety Glasses for Basic Frontal Protection

Safety glasses are extremely similar in design to everyday glasses, with the structural layout of their lenses and frames following the form of ordinary glasses. This design, which is close to that of daily glasses, makes the protective function of safety glasses have limitations. Their protective range mainly focuses on the "front of the eyeball". Through single or double lenses, they provide a protective barrier against objects, splatters, etc. that may fly from the front. However, the skin around the eyes and the lateral areas of the eyeballs are completely exposed. Once encountering impacts or splatters from the side, or splashes of chemical liquids, these vulnerable parts cannot be effectively protected.

Safety Goggles for 360° Fully Sealed Protection

The protection logic of safety goggles is "comprehensive wrapping". This design concept stems from in-depth consideration of the complex physiological structure of the eyes and risks in work scenarios. Safety goggles in our shop can not only fully cover the eyeballs, but also accurately cover the area from 1-2 centimeters above the eyebrow arch to below the cheekbones, and completely wrap the fragile skin on the sides of the eyes, forming a completely enclosed protective space. Even in environments with high dust concentration and frequent liquid splashing, it can prevent tiny particles or liquids from penetrating into the eyes.

Different Applicable Scenarios

The differences in protective capabilities between the two types of equipment directly determine their applicable scenarios. Safety glasses, featuring a single lens and adjustable temple design, can only provide basic protection against splashes and impacts, making them suitable for low-risk operations such as mechanical processing and assembly line work. However, in high-risk scenarios like chemical experiments, due to the lack of side and facial protection, the eyes are vulnerable to the risk of splashing reagents. Safety goggles, with a sealed surrounding lens, anti-fog coating, and adjustable headband, can comprehensively resist splashes, dust, and chemical liquids, as well as isolate irritating gases. Nevertheless, their sealing performance can cause the lenses to fog easily during daily operations and result in poor breathability, affecting vision and comfort. Therefore, the selection of protective equipment must match the needs of the scenario; otherwise, it may easily lead to protection failure or reduced user experience.

For Low-Risk Scenarios

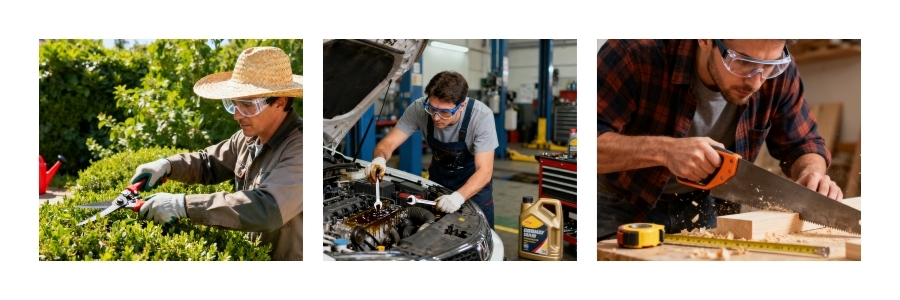

When the work scenario only involves the risk of "frontal solid particle impact" and is free from liquid splashes, fine dust, or chemical spray interference, safety glasses, with their lightweight design and good field of vision, become a more suitable choice. Such protective equipment usually uses single or double polycarbonate lenses, which can effectively resist particle impacts as small as 0.1 millimeters. Meanwhile, the open-sided structure reduces stuffiness and vision obstruction while ensuring basic protection, making them particularly suitable for working environments that do not require all-around protection, such as mechanical assembly and light grinding. Typical scenarios include:

- Mechanical processing and metal manufacturing: During lathe cutting, milling machine processing, and drilling operations, metal chips mostly fly out from the front, with no risk of lateral splashing, and safety glasses can effectively block them; when grinding metals, if only small workpieces are processed, the amount of dust is small and concentrated in the front, so safety glasses can also be used.

- Woodworking and furniture manufacturing: When sawing wood, planing wooden boards, and polishing furniture, wood chips mainly splash from the front and are relatively large in size, so the front protection of safety glasses is sufficient to deal with them; when assembling furniture, small screws and nails may slip from the hands and hit the eyes from the front, and safety glasses can prevent impact injuries.

- Daily light industry and maintenance operations: When assembling electronic components, small screws and solder dregs may fall from the front, and safety glasses can prevent foreign objects from entering; during home appliance maintenance, plastic debris and metal fragments generated from disassembling parts mostly impact from the front, so full-dimensional protection is not required.

For High-Risk Scenarios

When there are risks in the environment that require full-dimensional protection, such as liquid splashes, fine dust, chemical sprays, and droplets, safety goggles must be selected. This type of protective equipment adopts a fully enclosed design, forming a physical barrier through a face-fitting sealing ring and a wrap-around lens to effectively isolate potential threats. Typical scenarios include:

- Chemical experiments and chemical production: When handling acid-base solutions and organic solvents, improper operation may cause the solution to splash, resulting in eye burns; when mixing or heating chemical reagents, toxic sprays may also be generated. Therefore, sealed protection is required to prevent inhalation and eye contact.

- Medical and public health scenarios: When in contact with patients with infectious diseases (such as influenza and COVID-19), the droplets produced by patients' coughing and sneezing may carry viruses, so goggles are needed to block the route of eye infection; during atomization therapy and dental operations, drug sprays or saliva droplets are likely to come into contact with the eyes, and sealed protection is also required.

- Painting and spraying operations: When painting, spraying glue, and spraying coatings, atomized paint particles will float in the air. If they enter the eyes through gaps, they will cause irritation, allergies, and even damage the cornea.

- Work in high-dust environments: In scenarios such as ore grinding, cement mixing, and metal derusting, fine dust remains suspended in the air, and ordinary safety glasses cannot prevent dust from seeping in from the sides

Structural Designs under Different Protection Requirements

The significant difference in protection scope essentially stems from the completely different structural design concepts of the two types of equipment. Safety glasses adopt an open-frame structure, with the temples and the frame flexibly connected by hinges. The sides are mostly designed with hollowed-out ventilation holes or only retain simple wings. This design, which prioritizes "lightweight and breathability", while ensuring basic lateral protection, focuses more on meeting the comfort needs of long-term wear. Safety goggles, on the other hand, adopt a wrap-around full-enclosure design. The part where the frame fits the face is equipped with a soft silicone sealing ring, combined with an elastic headband with adjustable tightness, which can form a tight and gap-free protective space, effectively blocking the intrusion of dust, chemical splashes and even tiny particles.

Design Centered Around Protection and Lightness

Safety glasses focus on "high-frequency daily use" scenarios. In terms of structural design, they not only adopt lightweight materials to reduce the sense of pressure from long-term wearing, but also enhance air circulation through unique ventilation holes or breathable mesh designs to improve comfort during use. In addition, their simple frame shape balances aesthetics and practicality, making them suitable for frequent wear in various conventional environments such as offices and laboratories. While meeting users' daily protection needs, they do not affect work efficiency and mobility convenience. The specific features are as follows:

- Frame material and shape: Most are made of hard plastic or metal, lightweight (usually only 20-30 grams), with no obvious sense of pressure when worn; they are "flat-shaped" and keep a certain distance from the face instead of being a fitting design, leaving space for ventilation, but this also creates gaps.

- Fixing method: Mainstream styles use adjustable temples for fixation, similar to ordinary glasses, making wearing and taking off more convenient, suitable for scenarios that require frequent putting on and taking off (such as alternating operations and inspections in mechanical processing); a few styles used in heavy industry are equipped with auxiliary headbands to prevent the temples from slipping, but they still cannot change the nature of the open frame.

- Lens and additional protection: The lenses are connected to the frame in a spliced manner, with tiny gaps and no sealing; to make up for the insufficient side protection, some styles will add "detachable side protectors" (plastic sheet structures), but there is still a gap between the side protectors and the face, which can only block larger particles and cannot prevent liquids or fine dust; most lenses are made of impact-resistant materials (such as polycarbonate), which can resist the impact of solid particles from the front but have no anti-permeation function.

Design Centered Around Sealing

To achieve full-dimensional sealing protection, safety goggles adopt targeted designs in details such as the frame, fixing method, and lenses. Their frames are usually integrally formed with flexible and impact-resistant silicone or TPU materials. While fitting the facial contour, they form a physical barrier, effectively blocking the intrusion of splashes, dust, and chemical fumes. Additionally, sealing rings or embedded borders are added around them, seamlessly connecting with the frame to form 360° all-round protection from the top, sides to the bottom. Moreover, some high-end goggles are also equipped with detachable anti-fog linings and diversion hole designs, which improve wearing comfort and visual clarity while ensuring sealing performance.

- Frame material and shape: Mostly made of soft silicone or elastic rubber instead of hard plastic, which can fit according to the facial contour and reduce gaps (some styles also add anti-slip lines on the inner side of the frame to improve fit); The overall frame is "bowl-shaped" or "hood-shaped", completely covering the eye area.

- Fixing method: Most are fixed with elastic headbands instead of temples — the headband can be adjusted for tightness to ensure that the frame always fits the face tightly, avoiding frame displacement and gaps caused by head movements; Some lightweight styles are equipped with foldable temples, but still retain the headband design, taking into account portability and sealing.

- Lens and additional protection: Adopt "integrated sealed connection" without splicing gaps to prevent liquid or dust from seeping in from the connection between the lens and the frame; Some styles add "extended protective sheets" on both sides of the lens to further strengthen side protection while maintaining the sealing effect; For special scenarios (such as chemical experiments), the lenses are made of anti-corrosion materials to avoid damage by acid and alkali solutions.

Conclusion

Whether you choose safety glasses or safety goggles, you should prioritize the principle of "compliance first, scenario matching" to avoid protect failure due to improper selection. Safety goggles and safety glasses are not in a "upgrade and replacement" relationship, but rather "targeted solutions for different risk scenarios". The former is a "basic protector" in low-risk environments, while the latter is an "all-dimensional guardian" in high-risk scenarios. When making a choice, it is necessary to first clarify the type of risks in the working environment (whether there are liquids, fine dust, or sprays), and then match the equipment based on the protection range and structural design. Only through precise selection can "eye safety be fully ensured". If you want to purchase such products, welcome to visit the sisco online store. We believe our products can provide you with reliable and safe protection.