A vacuum leak tester is a non-destructive testing device designed to identify leaks in sealed packages, containers, or systems. It plays a critical role in ensuring product integrity by confirming that no contaminants or air can infiltrate, thus preserving the quality and safety of the product. In this blog by SISCO, we will comprehensively explain the basic, working process, aplications, benefits associated with vacuum leak tester, helping readers build a complete and systematic understanding.

Basic of Vacuum Leak Tester

The vacuum leak tester is an instrument used to detect leaks in a sealed product. The equipment creates a vacuum and measures the pressure loss over time. The leak detection instrument is an economical and proficient way to add quality control measures to your packaging application. It can be utilized for the detection of any leaks in a variety of packaging, right from food packets, frozen fruits, dairy products, bakery products, foil cups, pharmaceutical equipment, medicines, etc.

Working Process

The core of vacuum leak testing lies in its ability to identify even micro-sized cracks or gaps by leveraging pressure differentials. Here’s a step-by-step breakdown of the process:

- Preparation: The test specimen, such as a sealed package or container, is placed within the test chamber of the Vacuum Leak Tester. The specimen should be properly prepared and sealed according to the requirements of the test.

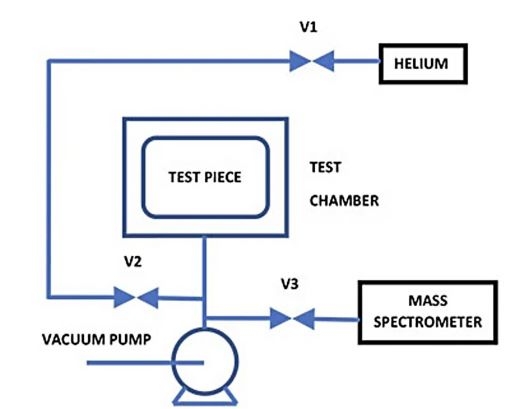

- Vacuum Creation and Helium Introduction: The vacuum leak tester creates a vacuum or low-pressure environment within the test chamber. This is typically achieved by using a vacuum pump (aided by valve V2 to control the vacuuming process) or similar mechanism. Meanwhile, valve V1 can be used to introduce helium into the system as needed, which can enhance leak detection sensitivity. The vacuum chamber is sealed to prevent any external air from entering during the test.

- Stabilization: Once the vacuum is established, the system allows the test specimen to stabilize within the vacuum chamber. This allows the pressure inside the specimen to equilibrate with the low-pressure environment.

- Pressure Measurement: The vacuum leak tester monitors and measures the pressure within the test chamber and the specimen. This is typically done using pressure sensors or transducers that accurately detect even small pressure changes. Valve V3 can be utilized to control the flow of gas to the mass spectrometer for more precise pressure - related analysis during this process.

- Leak Detection: If there is a leak or defect in the test specimen, the pressure inside the specimen will change due to the influx of air from the surrounding environment or the escape of helium (if helium was introduced). The vacuum leak tester detects this change in pressure as an indication of a leak.

- Pressure Decay Analysis: The vacuum leak tester analyzes the pressure data over a specific time period. It compares the pressure change rate with predetermined criteria or acceptable limits to determine if the test specimen has passed or failed the leak test.

- Test Result Display: The vacuum leak tester displays the test results indicating whether the specimen has passed or failed the leak test. This can be shown on a digital display, through an audible alarm, or via a connected computer interface.

Applications Scenarios

A vacuum leak tester is not just a “quality check tool”—it’s a versatile solution that supports every stage of production and product development. Its primary applications include:

- Chamber Setup: Place the sealed test specimen (e.g., a bottle or package) inside the tester’s airtight chamber. Ensure the specimen is properly sealed per test requirements.

- Vacuum Creation: A vacuum pump or similar mechanism evacuates air from the chamber, creating a low-pressure (vacuum) environment. The chamber is sealed to block external air from entering during testing.

- Stabilization Phase: The system pauses to let the specimen’s internal pressure equilibrate with the vacuum in the chamber—ensuring accurate measurements

- Pressure Monitoring: High-sensitivity pressure sensors or transducers track pressure levels inside both the chamber and the specimen, detecting even minute changes.

- Leak Identification: If the specimen has a leak, air from the chamber (or surrounding environment) will seep into it, causing a measurable pressure shift. The tester flags this shift as a leak.

- Pressure Decay Analysis: The tester analyzes pressure changes over a set time, comparing the rate of decay to preconfigured acceptable limits. This determines if the specimen passes or fails.

- Result Display: Test outcomes (pass/fail) are shown via a digital screen, audible alarm, or connected computer interface—for quick, clear decision-making.

Note: Features vary by model and manufacturer. Advanced testers may include multi-chamber setups, customizable test parameters, data logging, and AI-powered analysis algorithms to boost accuracy and efficiency.

Advantages of Vacuum Leak Tester

Adding a vacuum leak tester to your testing lab or production line is one of the most wise decisions you might make that will not only improve the quality of your products but also save you lots of money. Here are the advantages of such equipment:

- Increased Production Efficiency

A vacuum leak test machine dramatically cuts down on the hours spent conducting a manual survey on the products. Vacuum testing, therefore, is much faster, thereby leading to more throughput. Automating the task of leak detection frees up your team to seek other critical jobs that have to be addressed. This increases the general productivity of the entire team. Labs implementing vacuum leak testers report a 30-40% increase in testing efficiency. - Reduced Product Failures

Understandably, hidden leaks have the potential to cause product failure, which will happen when pertaining to packaging and medical devices. However, with actual vacuum leak testing, one may catch those potential issues before they ever reach the consumer, hence preventing costly recalls and warranty claims. This could reduce post-sale defects by 20-25%. - Better Compliance with the Standards of the Industry

This is very true in many industries that hold very strict regulations on such products, having to undergo tedious tests, such as leak testing. SISCO's vacuum leak test for bottles are all in compliance with international standards, such as those issued by ASTM and ISO, which will therefore make your company processes compliant. Reducing your chances of drawing fines, penalties, and delays may save your company hundreds of thousands of dollars in unrealized costs. - Cost Savings on Materials

This can be optimized by using a vacuum leak tester so that the products that are sealed and ready go on to further stages of processing or packaging. These assure less waste, better use of raw materials, and even savings on material usage of up to 15-20%. - Data accuracy and quality control

vacuum leak test for bottles provide you with accurate and reliable results, enabling quality control to be carried out far more accurately. The knowledge gained from the test can then be used to make refinements and adjust production processes by designers. Good data produces good decision-making, less error, and more high-quality products, saving on costly rework and repairs.

Conclusion

To sum up, the vacuum leak tester stands as an indispensable asset for businesses relying on sealed products. Its science-backed working principle (leveraging pressure differentials) and wide-ranging applications—from food packaging to pharmaceuticals—make it a cornerstone of quality control. Beyond boosting efficiency and cutting costs, it ensures compliance, reduces product failures, and upholds brand trust. Investing in a model tailored to one’s industry needs isn’t just a cost-saving move; it’s a strategic step to secure product integrity and long-term profitability in competitive markets. Elevate your project precision with our premium vacuum leak tester available at sisco.com! Designed for both professionals and enthusiasts, this advanced tester will help you detect leaks with unmatched accuracy.