In today’s landscape of stringent quality standards and industry regulations, choosing the right leak tester is essential whether you’re a quality manager ensuring product integrity, a lab researcher validating precision components, or a business owner minimizing losses from defective goods. This guide will help you shop for and select the perfect leak tester to meet your specific needs, with insights into why you need one, how to match it to your application, key factors to consider, and our available SISCO leak testers for purchase.

Contents

- Why Do I Need a Leak Tester?

- Know Your Application Area Before Purchasing

- 6 Key Factors to Consider When Buy a Leak Tester

- SISCO Leak Tester for Sale

Why Do I Need a Leak Tester?

A leak tester is a specialized device designed to detect and measure unintended gaps, holes, or cracks in products, components, or systems—preventing the escape of gases, liquids, or vacuum. Investing in a leak tester offers critical advantages that make it a must-buy for many industries:

- Ensure product safety & compliance: It guarantees product safety (e.g., maintaining medical device sterility) and compliance with industry regulations (e.g., food packaging airtightness standards), helping you avoid penalties from non-compliance.

- Protect product performance: For components like automotive fuel systems, it detects leaks that could cause performance failures, reducing post-sale repairs and customer complaints.

- Minimize losses: By identifying defective goods early in production, it cuts down on losses from scrapped or recalled products, saving your business costs.

- Versatile functionality: Leak testers use diverse technologies ( test vacuum decay, high-voltage discharge, air pressure testing, etc.) to suit different needs, making them a flexible tool for various testing scenarios.

Know Your Application Area Before Purchasing

Before you buy a leak tester, clearly defining your application area is crucial—it directly determines which type of tester will work best for you. Different application areas demand unique features, accuracy levels, and testing speeds:

- Packaging (Food & Pharmaceuticals): If you work with sealed packages like snack pouches, blister packs, or vials, you need to purchase non-destructive, fast-testing leak testers. These testers verify airtightness without damaging packages, ensuring product freshness, sterility, and shelf life while meeting food safety or pharmaceutical regulations.

- Laboratory Research: For labs developing precision components (e.g., medical devices, aerospace parts), select high-accuracy, sensitive leak testers. These devices deliver precise measurements to validate critical prototypes and materials, meeting the strictest performance standards.

- Automotive & Heavy Industry: If you manufacture engines, fuel systems, or hydraulic components, buy durable, reliable leak testers that handle rugged parts and high-pressure/high-vacuum environments. They detect leaks in safety-critical components to prevent on-site failures.

- Multi-Channel & Batch Testing: For operations testing multiple parts simultaneously (e.g., electronics manufacturers testing batches of connectors), purchase multi-channel leak test systems. These boost efficiency in high-volume production by testing several components at once.

- General Air Pressure Leak Checks: For quick, cost-effective leak tests on valves, hoses, or small enclosures, choose air pressure leak testers. They are user-friendly and rapid, ideal for routine quality checks where speed and simplicity are key.

6 Key Factors to Consider When Buy a Leak Tester

When shopping for a leak tester, evaluating these 6 key factors ensures you select a product that matches your needs and offers long-term value:

(1) Testing Technology

The core of a leak tester is its technology—each type suits specific applications, so choose the one aligned with your product type and testing environment:

- Vacuum Decay: Uses pressure changes in a sealed space to detect leaks; best for sealed containers and packaging.

- High-Voltage Discharge: Detects leaks in conductive materials; ideal for industrial or automotive components.

- Air Pressure Decay: Measures pressure changes in air-pressurized parts; suited for general components like valves or hoses.

- Multi-Channel Vacuum: Tests multiple parts at once; perfect for high-volume batch production.

(2) Sensitivity & Accuracy

- Sensitivity: Refers to the smallest leak the tester can detect (e.g., 1×10⁻⁶ mL/s vs. 1×10⁻⁹ mL/s). Prioritize higher sensitivity when buying for critical applications (e.g., medical devices, aerospace), where tiny leaks risk safety or performance. For non-critical uses (e.g., plastic toy enclosures), lower sensitivity may suffice.

- Accuracy: Ensures consistent results. Select testers calibrated to industry standards (e.g., ISO, ASTM) and with regular calibration support—this guarantees reliable data for quality checks.

(3) Testing Speed & Throughput

Speed directly impacts productivity, especially for manufacturing lines:

If you need to test high volumes, buy an automated leak tester that handles hundreds of parts per hour (with conveyor integration).For low-volume or batch testing, a semi-automated model is more cost-effective (manual/portable models may take 10–30 seconds per test).

(4) Portability & Size

Choose a size and portability level based on your testing location:

- Portable testers: Ideal for fieldwork (e.g., HVAC repairs) or testing large, immovable equipment (e.g., industrial tanks). Look for lightweight designs (<2 kg) and rechargeable batteries when purchasing.

- Benchtop/Stationary testers: Better for lab or factory QC (parts are brought to the tester). They offer higher accuracy but lack mobility—select this type if testing is done in a fixed location.

- In-line testers: Integrated directly into production lines for real-time testing; buy this for high-volume manufacturing.

(5) Ease of Use & Maintenance

- User interface: Select testers with a clear touchscreen, simple "start/test" buttons, and visual/audio pass/fail alerts—this reduces training time and human error.

- Maintenance: Choose testers with easy-to-replace parts (e.g., filters, sensors) and minimal upkeep. Disposable seals/adapters (for different part sizes) enhance hygiene and flexibility, lowering long-term maintenance costs.

- Connectivity: For compliance, buy models with USB, Ethernet, or Wi-Fi connectivity to export test data to quality management software.

(6) Compliance & Certifications

Ensure the leak tester you purchase meets industry-specific standards—this validates your test results for audits and regulatory submissions:

- Medical devices: FDA, CE (MDR)

- Automotive: ISO 12100, IATF 16949

- Food packaging: FDA 21 CFR, EU 10/2011

SISCO Leak Tester for Sale

To help you easily purchase the right leak tester, we’ve listed our available SISCO models with key specs and prices below. You can select the one that fits your application and budget directly:

| Product Name | SKU | Key Application | Price |

Vacuum Leak Tester For Packaging |

SISCO-VLD-MFY-05A | Sealed food/pharmaceutical packaging (e.g., snack pouches, vials); high efficiency, easy operation |

$2,760.54 |

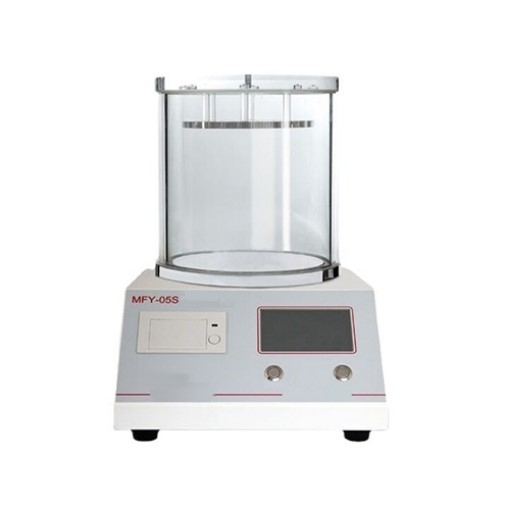

Vacuum Leak Detector For Lab |

SISCO-VLD-MFY-05S | Laboratory precision component testing (e.g., medical device prototypes); high accuracy, compact design |

$3,836.46 |

Vacuum Decay Leak Tester |

SISCO-VLD-MFY-HS | Sealed containers requiring vacuum decay technology; stable performance, wide pressure range |

$10,978.46 |

Package Leak Tester For Food/Pharmaceutics |

SISCO-VLD-MFY-06S | High-demand food/pharmaceutical packaging (ensures sterility & freshness); sterility-focused, fast testing |

$8,408.08 |

High Voltage Discharge Vacuum Leak Detector |

SISCO-VLD-LEAK-HV | Conductive materials in industrial/automotive components; strong anti-interference, high sensitivity |

$51,078.46 |

Multi-Channel Vacuum Leak Detector |

SISCO-VLD-LEAK-M | High-volume batch testing (e.g., electronics connectors); multi-channel parallel, time-saving |

$10,948.77 |

Air Pressure Leak Tester |

SISCO-VLD-YD-T02 | General components (valves, hoses) for quick air pressure checks; versatile, low maintenance |

$3,963.46 |

Digital Air Leak Tester |

SISCO-VLD-YD-T01 | Routine quality checks for small enclosures/parts; digital display, intuitive operation |

$3,132.69 |

Our SISCO leak testers are engineered to meet diverse industry needs—ensuring product quality, safety, and compliance. If you need help selecting the right model for your specific application, contact our team at sisco.com for personalized guidance before you buy.